Circularity

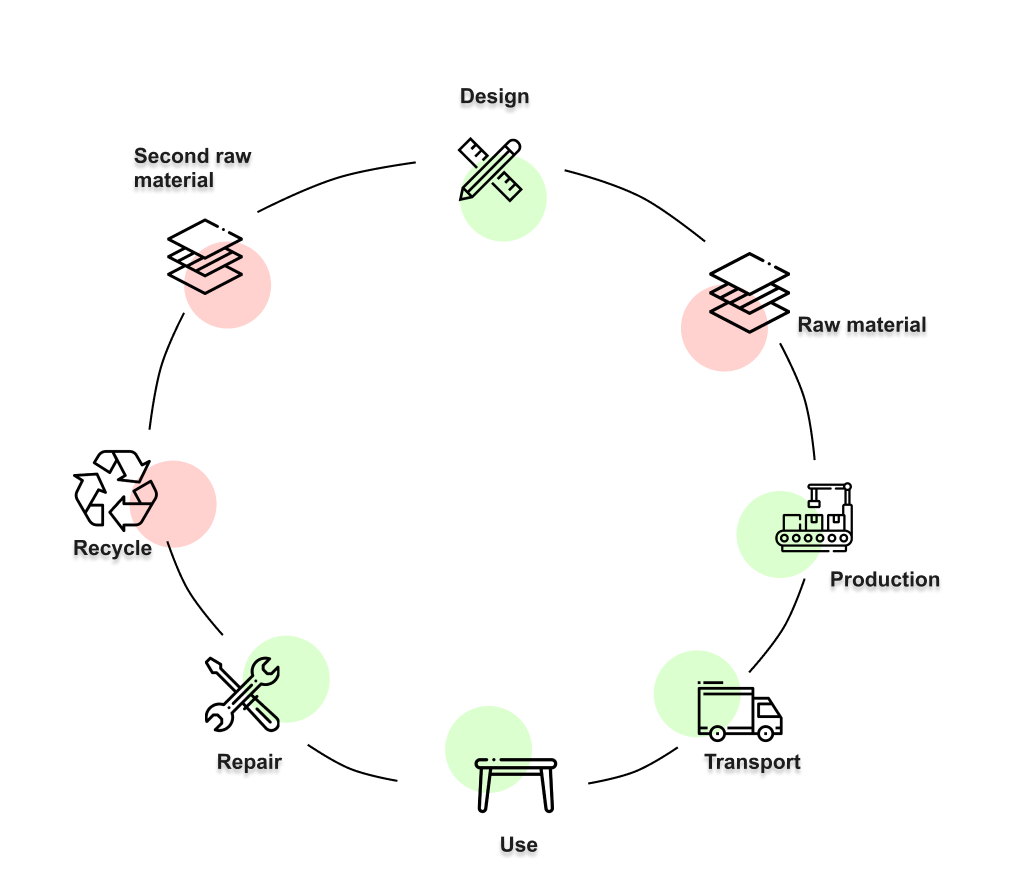

We tackle three important aspects in our process to increase our circularity percentage:

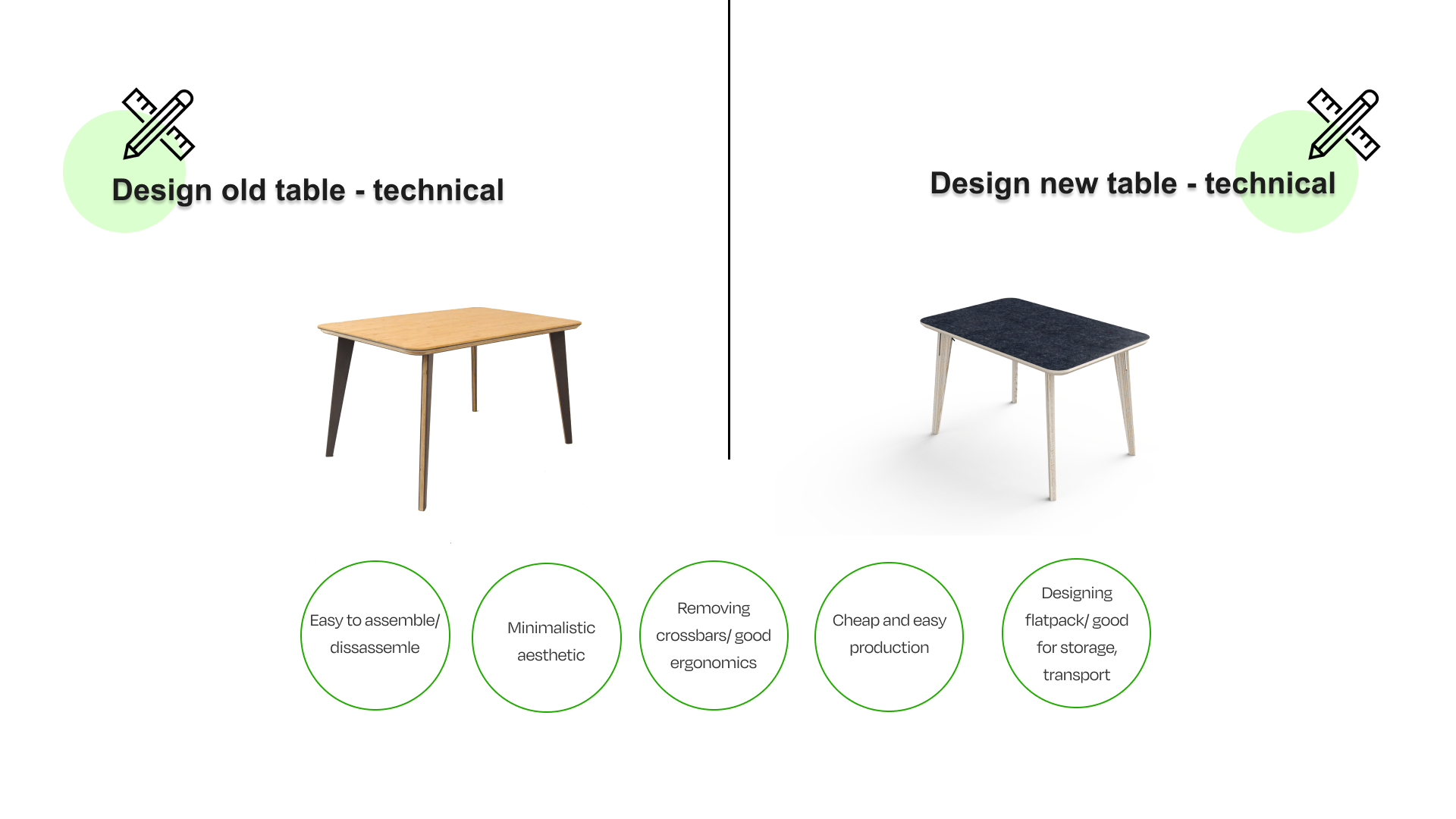

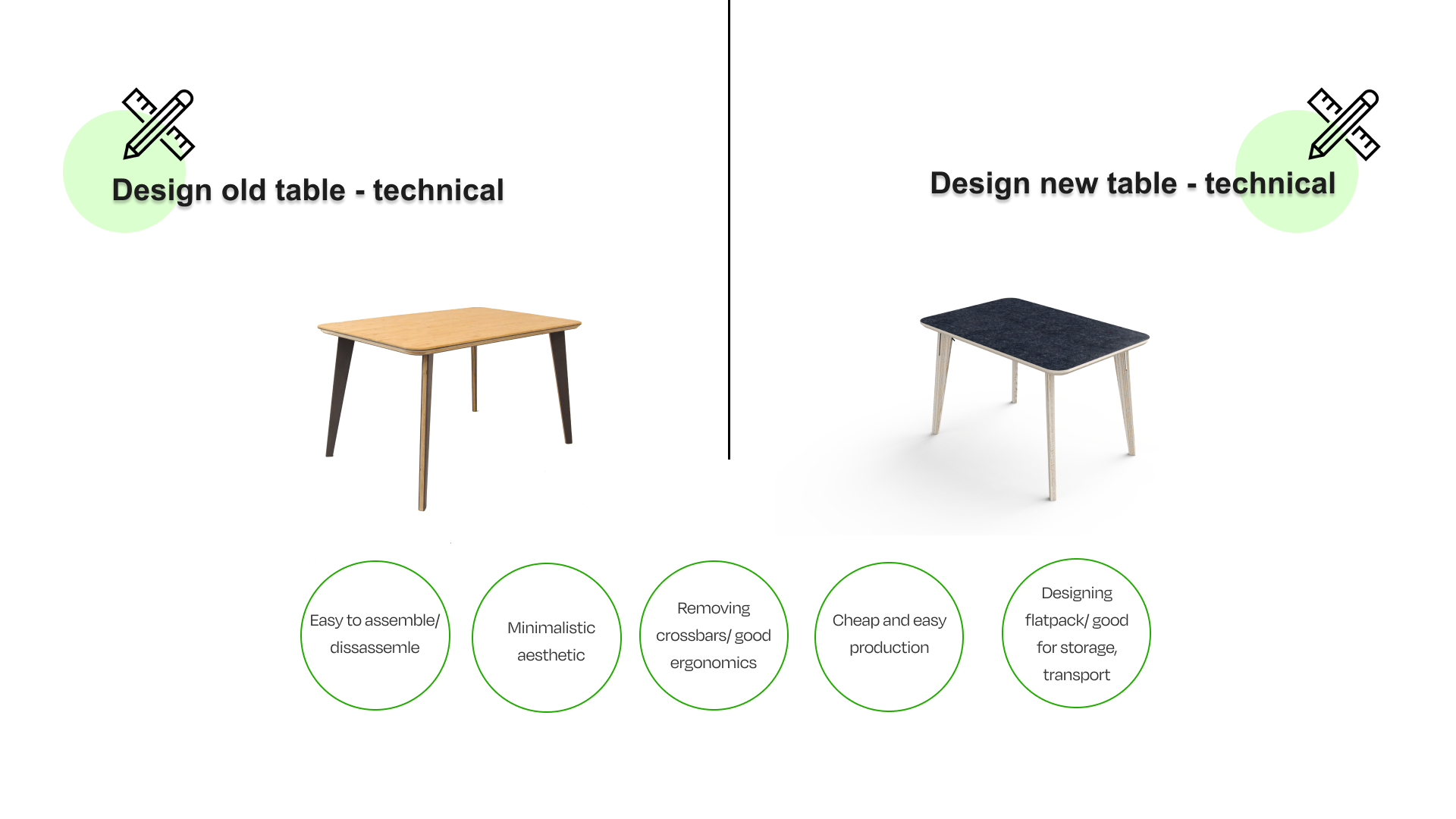

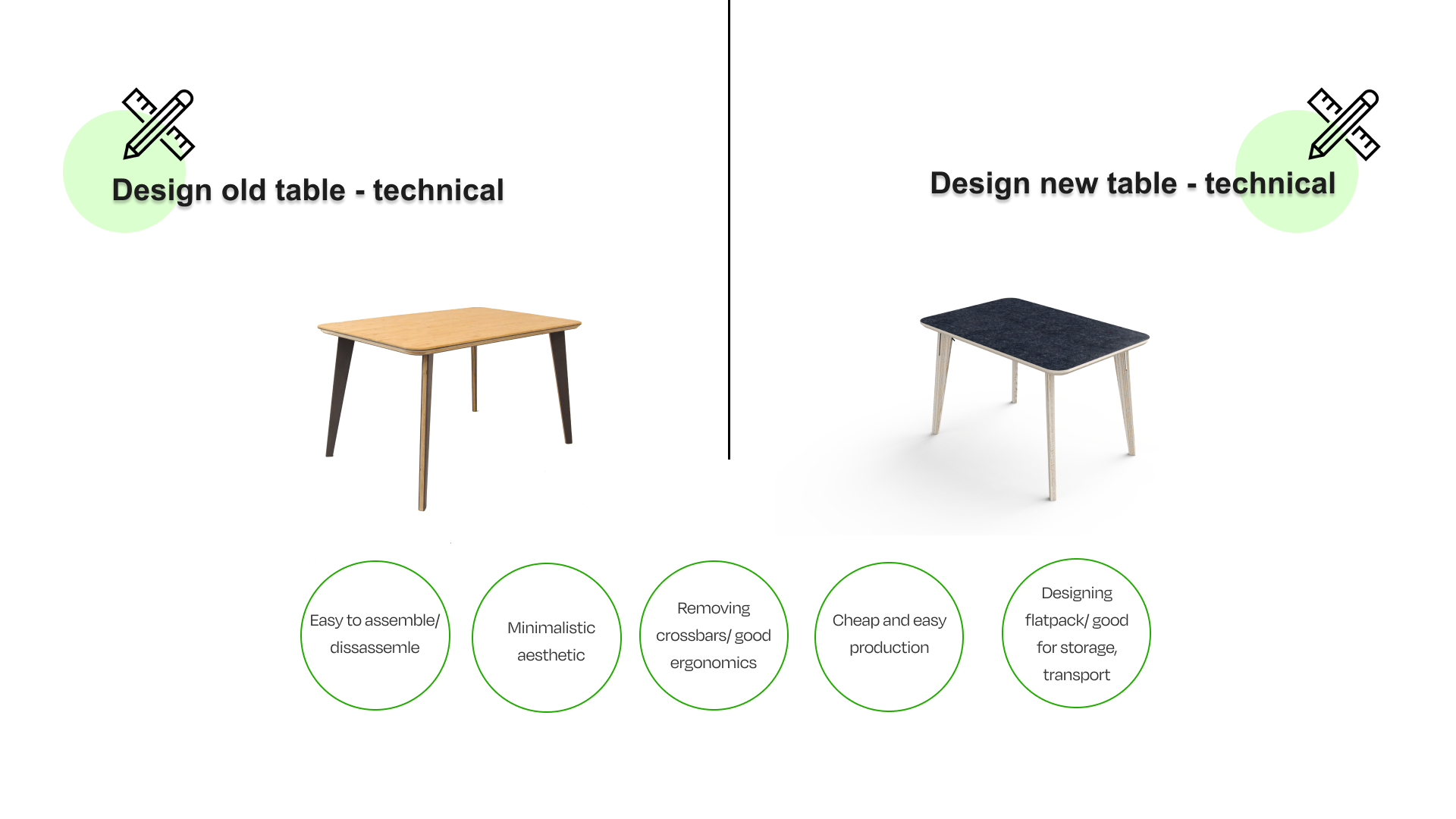

The first being the product transportation; designed and manufactured in a way that allows it to be efficiently packed and transported in a compact form before assembly, contributing to a decrease in fuel consumption and emissions.

For the second point we have the material choice, with optimization as the main goal, from a design that reduces the structural elements, it is possible to minimize the amount of materials needed for the table.

We also considered only long lasting quality materials which have a low environmental impact in their production and can be recycled and reused when finishing its life cycle.

Thinking about both durability and resilience, we have chosen Bamboo as one of our materials. In the event of scratches or wear, the tabletop can be sanded multiple times, up to approximately 10 rounds of sanding, without compromising its integrity.

Third point would be product extension life. We have also created a whole system around the table, making it possible for the user to order individual replacement parts in the unfortunate event of a broken table leg or tabletop. By doing so, the user can avoid the need to purchase an entirely new table, saving both your time and resources.

Your Content Goes Here